Types of Wooden Chopping Board

The second part of the Art & Science of Chopping Boards briefly looks at the different types of board and design considerations!

Edge Grain

Made from the sides of parallel strips of wood which are glued together to form a flat surface.

Probably the most common type of wooden board, as the construction of this style of board means thinner and lighter boards can be made, as well as thicker ones. Different types of wood can also be used to make striking designs.

The hard surface of edge-grain boards are durable and less prone to warping, but cutting across the grain means they are susceptible to knife marks and can dull your knife’s edge over time. Regular oiling/conditioning is a must to prevent cracking and splitting.

Face Grain

Simply the top of a piece of wood - a single slab and often features a waney or ‘live’ edge.

Single slab boards showcase the most attractive part of the grain pattern with each one totally unique. These are the most natural as they do not require any glue to make making them plastic/toxic free, which for me is a huge bonus!

This style of board requires regular oiling/conditioning to prevent it from drying out and cracking. Also as cutting is done across the grain scratches are easier to see and can dull a knife’s edge over time.

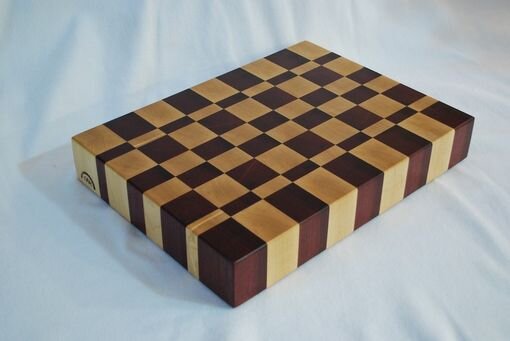

End Grain

Multiple pieces of wood cut into short strips and turned so their ends form a flat surface then glued together.

End-grain boards are the most expensive type of chopping board which are used as traditional butchers’ blocks and often by professional chefs.

By exposing the softer end-grain fibres which face upwards to form the cutting surface, allows the wood to ‘self-heal’ and spring back to shape, as well being able to absorb more force. This means greater resilience to scratches and dents whilst better retaining a knife’s edge.

These boards require lots of glue to connect the various squares of wood, and demand regular oiling and conditioning to keep the board hydrated and prevent it from cracking/splitting.

Features

Bark / ‘Live Edge’

Although it can provide a great rustic feature, I do not recommend leaving bark on for hygiene reasons - it is hard to properly clean and provides a great place for bacteria to grow in.

There are also thousands of different insect, beetle, worm and larvae species that are attracted to bark, primarily as a source of food.

Eventually any bark left on will peel off anyway, especially after regular cleaning and drying; leaving an untreated, un-crafted side on show.

Liquid Channels

A great feature for boards of all sizes - these grooves will collect excess liquid and prevent it from running off onto the work surface. I try to only include two horizontal channels so that each edge of the board can be used to scrape off chopped food without getting caught!

Rubber Feet

An underrated feature that is especially suited to larger heavy boards. These provide good grip to prevent sliding when chopping. The feet raise the board up stopping liquid from running underneath and makes it easier to pick up - so no more using tea towels under your chopping board!

Finishes

Choosing an appropriate finish for chopping boards is absolutely essential, as this is what will be in contact with your food and your precious knives! Again there is a lot of conflicting information online so I will try and keep this section short and sweet. I should also mention that it is important to check only food-safe, non-toxic glue is used for Edge and End grain boards!

Food-Grade Mineral Oil

The industry standard for finishing and conditioning (or ‘seasoning’) chopping boards and butcher block surfaces. Only food-safe BP / FDA / USP approved pure mineral oil should be used; which is considered non-toxic, colourless, odourless, tasteless and will not go rancid. This oil is very affordable and is effective in penetrating the wood to hydrate it and provide a water-resistant finish.

Mineral oil however is a by-product of the refining of crude oil and a distillate of petroleum. In a world where we desperately need to move away from using non-renewable fossil fuels, seeking a more natural alternative that doesn't involve using a petroleum product that is in constant contact with our food, seems like a positive step in the right direction!

Organic Alternatives

Linseed, Walnut, Tung and Coconut oils each have their own unique benefits, and are often used as viable finishes on chopping boards. If using nut oils, do so with caution as those who suffer from nut allergies may be effected. Their main drawback though is that they are organic oils, which will eventually go rancid when the natural fats contained within them auto-oxidises. Vegetable oils such as olive or sunflower will also go rancid - but much faster than the aforementioned so I certainly don’t recommend their use as a chopping board finish.

Rancid oils smell ‘gone off’ and can affect the taste of the food they come into contact with, and while they won’t necessarily make you sick in the short term, they contain something called ‘endogenous free radicals’ (albeit small amounts) which contribute to oxidative stress - this is a rabbit hole so feel free to do your own research into this!

Other Finishes

Polyurethane varnishes or lacquers are often toxic to humans and not suitable for regular contact with food. The protective layer they form is also easily cut through and chipped, meaning small fragments can enter the food being prepared on the surface.

Similarly shellac and Osmo hardwax/oils, although highly water resistant and food-safe, are non-penetrative finishes that form a hard layer on top of the wood which quickly deteriorates and visibly scars when being chopped on, exposing the bare wood underneath which can then harbour bacteria and is susceptible to cracking.

Fractionated Coconut Oil

This is a great plant-based alternative to petroleum based mineral oil products, and is equally as effective at hydrating and protecting wooden boards, as well as enhancing their appearance!

FCA is produced using a process called fractionation (steam distillation) which is achieved by heating the oil to separate different fats naturally contained in coconut oil. By removing long-chain fatty acids and keeping the medium-chain fatty acids, you are left with a more stable oil that will not go rancid. This refined oil has a huge variety of uses and can be found in many foods and dietary supplements, as well as being widely used in the cosmetic industry.

I use the finest quality food-grade fractionated coconut oil to condition my boards, that is ethically sourced and certified cruelty free - however please note it cannot be guaranteed free from traces of nuts or other allergens due to the factory it is produced in!

Find out more on the next page…